5-16 inch Stainless Steel Ball

5-16 inch Stainless Steel Ball Specification

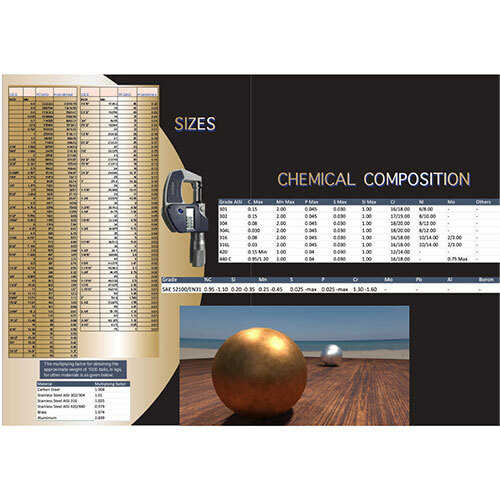

- Hardness

- HRC 55-60

- Size

- 5/16 inch

- Product Type

- Steel Ball

- Material

- Stainless Steel

- Steel Grade

- AISI 304/316 Stainless Steel

- Diameter

- 7.938 mm Millimeter (mm)

- Surface

- Other

- Application

- other

- Weight

- Approx. 0.95 g (Single Ball) Grams (g)

- Color

- Silver

- Temperature Tolerance

- Up to 400C

- Magnetic Property

- Non-magnetic (316), Slightly magnetic (304)

- Precision Grade

- G100

- Finish Type

- Mirror finish

- Manufacturing Process

- Cold forged and hardened

- Tensile Strength

- Approximately 580 MPa

- Corrosion Resistance

- High

- Density

- 7.85 g/cm

- Rust Proof

- Yes

About 5-16 inch Stainless Steel Ball

- Size: 5/16 (in inches)

- Material: SS, Stainless Steel, MS, Mild Steel, Carbon steel, Carbon Hard steel, Carbon soft steel, HCHCr steel, HCHC steel, AISI 52100, Chrome steel, SAE52100, EN31 steel.

Superior Strength and Durability

These stainless steel balls are crafted using cold forging and hardening processes, resulting in exceptional tensile strength and hardness. With a uniform solid build and precision G100 grade, they ensure lasting performance even under demanding conditions. Suitable for heavy-duty industrial and automotive applications, their structural reliability stands out.

Outstanding Corrosion Resistance

Made from AISI 304/316 stainless steel, these balls resist rust and corrosion, making them perfect for applications exposed to moisture, chemicals, or extreme temperatures. Their mirror finish not only enhances appearance but also bolsters their protective properties, ensuring longevity in challenging environments.

Precision for Critical Applications

Offering G100 precision and a mirror-polished surface, these balls deliver consistent accuracy in size (7.938 mm diameter) and weight for optimal bearing and mechanical functionality. They are widely used in high-performance bearings, valves, and various industrial machinery where exact tolerances are crucial.

FAQ's of 5-16 inch Stainless Steel Ball:

Q: How do I select between the 304 and 316 stainless steel ball grades for my application?

A: Choose 316 stainless steel balls for environments demanding maximum corrosion resistance and complete non-magnetic properties. Opt for 304 stainless steel balls if slight magnetic response is acceptable, and you still require high corrosion resistance and strength.Q: What manufacturing process is used to create these stainless steel balls?

A: These balls are manufactured using a cold forging and hardening process, which enhances their density, hardness (HRC 55-60), and tensile strength while preserving a uniform, solid structure.Q: Where are these stainless steel balls commonly used?

A: They are used in a variety of applications including industrial bearings, precision valves, automotive components, and other mechanical systems requiring durable and corrosion-resistant ball bearings.Q: What is the benefit of the G100 precision grade and mirror finish?

A: The G100 grade ensures tight diameter tolerances for reliable performance in critical mechanisms. The mirror finish enhances surface smoothness, reducing friction and wear in high-speed or high-load applications.Q: How should these stainless steel balls be used to maximize their lifespan?

A: They should be installed in clean environments and paired with compatible lubricants when used in bearings or machinery, ensuring their corrosion resistance and hardness properties deliver maximum durability over time.Q: When is it necessary to consider the temperature tolerance of these balls?

A: If your application operates at temperatures up to 400C, these balls are suitable. Their high temperature tolerance makes them ideal for automotive and industrial settings exposed to significant heat.Q: What advantages do these balls offer to dealers, retailers, and importers in India?

A: Their corrosion resistance, precise specifications, and adaptable use across industries make them a popular, versatile product for dealers, retailers, and importers catering to diverse industrial, manufacturing, and automotive markets in India.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Stainless Steel Ball Category

1/16" STAINLESS BALL 304

Minimum Order Quantity : 10 Kilograms

Surface : Shiny

Application : Bearings, other

Hardness : 1025 HRC (annealed) to 2539 HRC (cold worked).

Size : Standard

Material : Stainless Steel

1-4 inch Stainless Steel Ball

Minimum Order Quantity : 10 Kilograms

Surface : Other

Application : other

Hardness : HRC 5558

Size : 14 inch

Material : Stainless Steel

5-32 Inch Stainless Steel Ball

Surface : Other

Application : other

Hardness : HRC 5560

Size : 5/32 Inch

Material : Stainless Steel

5-8 inch Stainless Steel Ball

Surface : Other

Application : other

Hardness : HRC 5560

Size : 5/8 inch

Material : Stainless Steel

NEXTAA INTERNATIONAL

GST : 27BIEPJ2813H1ZH

GST : 27BIEPJ2813H1ZH

PLOT 160 / 161, SHOP NO 2, SAHAKAR NIWAS CHS LTD, Jawahar Nagar Road NO. 2, Goregaon WestMumbai - 400104, Maharashtra, India

Phone :08045477176

|

SANJAY BALL CO.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry