1/16" imitation steel ball

Price 150 INR/ Kilograms

MOQ : 50 Kilograms

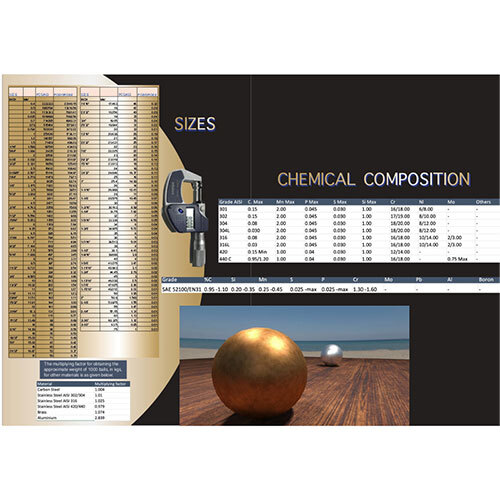

1/16" imitation steel ball Specification

- Size

- Standard

- Hardness

- Rigid

- Material

- Stainless Steel

- Surface

- Shiny

- Application

- Bearings

- Color

- Silver

1/16" imitation steel ball Trade Information

- Minimum Order Quantity

- 50 Kilograms

- Supply Ability

- 5000 Kilograms Per Month

- Delivery Time

- 7 Days

- Main Domestic Market

- All India

About 1/16" imitation steel ball

Stainless steel balls are manufactured from steel containing at least 12% chromium, and sometimes other alloying elements, making them corrosion-resistant and durable. They come in various grades and can be magnetic or non-magnetic, depending on their heat treatment and composition. These balls are widely used in applications requiring durability, low friction, and resistance to corrosion, such as bearings, valves, and medical equipment.

Key Features and Properties:

-

Stainless steel balls are known for their resistance to rust, staining, and corrosion, making them suitable for harsh environments.

-

They also have high tensile strength, even at low temperatures.

-

The hardness of stainless steel balls can vary depending on the heat treatment (annealed, cold worked, hardened) and grade, with hardness values ranging from 10-25 HRC (annealed) to 25-39 HRC (cold worked).

-

Stainless steel balls are used in a wide range of applications, including:

- Bearings: They are a key component in various ball bearings, providing smooth and efficient rotation.

- Valves: Used in valves for precise flow control and resistance to corrosion.

- Medical Equipment: Employed in medical instruments and devices due to their antibacterial and hypoallergenic properties.

- Food Processing: Used in food processing equipment for their resistance to corrosion and hygiene.

- Industrial Applications: Found in pumps, sprayers, and other industrial machinery.

- Bearings: They are a key component in various ball bearings, providing smooth and efficient rotation.

Types of Stainless Steel Balls:

-

These balls are characterized by their high chromium content, providing good corrosion resistance and hardness.

-

This type contains both chromium and nickel, enhancing corrosion resistance and toughness.

-

Common grades include SS 304, SS 316, and SS 316L, each with specific properties and applications.

Examples of Applications:

- Ball Bearings: Used in various machinery and equipment for smooth and efficient rotation.

- Valve Components: Employed in valves for precise flow control and durability.

- Medical Equipment: Used in medical instruments and devices due to their biocompatibility and corrosion resistance.

- Marine Applications: Used in marine equipment and components exposed to saltwater, benefiting from their resistance to chloride-induced corrosion.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Steel Ball Category

1/16" HCHC

Price 370 INR / Kilograms

Minimum Order Quantity : 10 Kilograms

Material : Stainless Steel

Size : Standard

Surface : Shiny

1/16" high carbon high chrome

Price 370 INR / Kilograms

Minimum Order Quantity : 10 Kilograms

Material : Stainless Steel

Size : Standard

Surface : Shiny

1/16 inch ss 304

Price 500 INR / Kilograms

Minimum Order Quantity : 10 Kilograms

Material : Stainless Steel

Size : Standard

Precision Steel Ball

Price Range 3.00 - 10.00 INR / Piece

Minimum Order Quantity : 50 Pieces

Material : Stainless Steel

Size : Customized

Surface : High Polished

NEXTAA INTERNATIONAL

GST : 27BIEPJ2813H1ZH

GST : 27BIEPJ2813H1ZH

PLOT 160 / 161, SHOP NO 2, SAHAKAR NIWAS CHS LTD, Jawahar Nagar Road NO. 2, Goregaon WestMumbai - 400104, Maharashtra, India

Phone :08045477176

|

SANJAY BALL CO.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry